Looking to buy or sell a Marco Polo? You can now advertise from just £9.99 Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

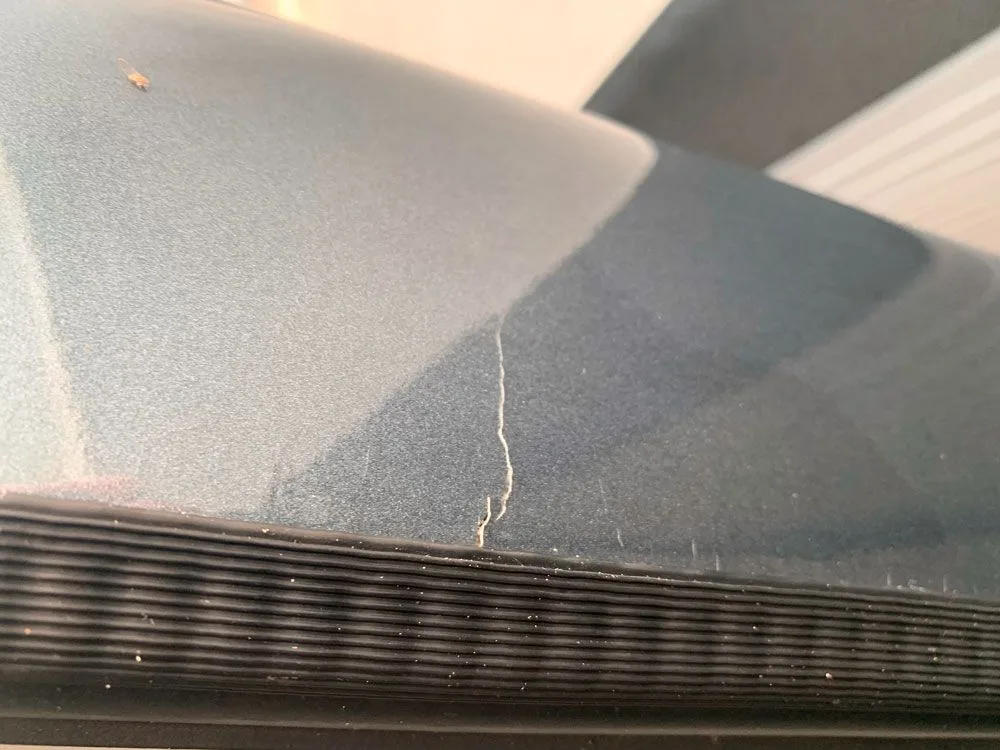

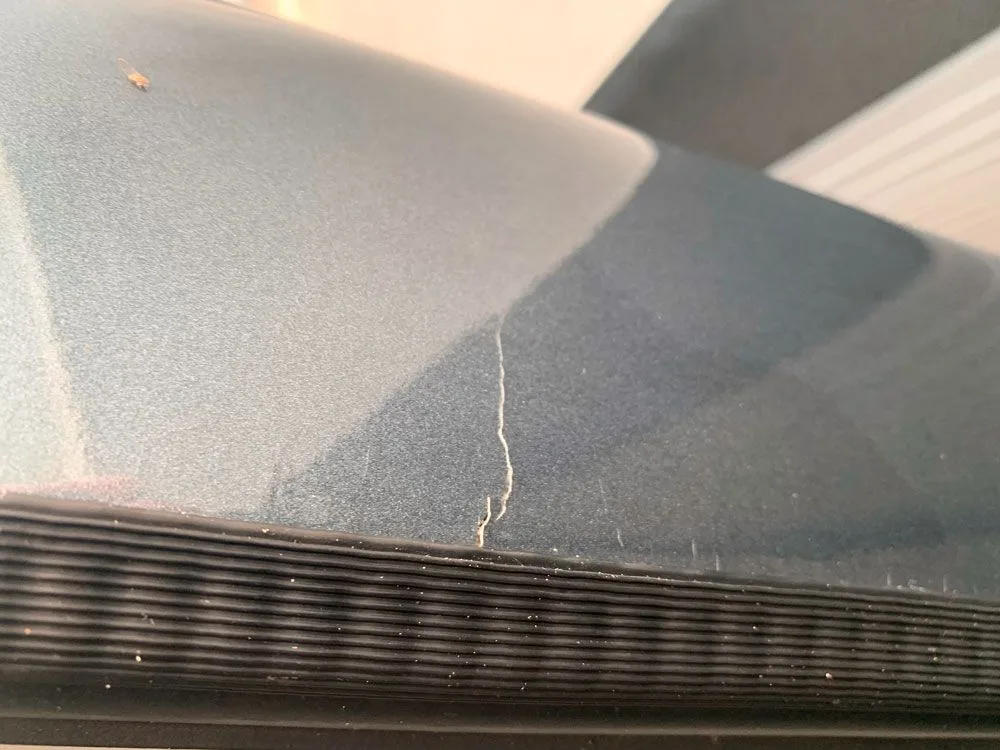

Cracked roof!

- Thread starter persuaders

- Start date

Hi all

My roof is also getting replaced due to the blister problem. It has been ordered since August.

When talking to my local MB dealer he told me that he had changed 3 before me and in an other case had to repair one. He fitted carbon plates in the interior of the roof in order to prevent from further cracking. I asked him to fit these carbon plates when he will fit my new roof. I am also very anxious to get these roof cracks or any other roof problem after a new roof fitting...

Maybe something to discuss with dealers when getting the new roof fixed.

My roof is also getting replaced due to the blister problem. It has been ordered since August.

When talking to my local MB dealer he told me that he had changed 3 before me and in an other case had to repair one. He fitted carbon plates in the interior of the roof in order to prevent from further cracking. I asked him to fit these carbon plates when he will fit my new roof. I am also very anxious to get these roof cracks or any other roof problem after a new roof fitting...

Maybe something to discuss with dealers when getting the new roof fixed.

Peter

Member

The carbon plates sound like an interesting option. Thank you for that.

Our cracked roof repair isn't covered under Warranty due to the age of the vehicle. Also, we have been told that there is no roof availability at present. I think we will just leave it for now and pick it up again next year when possibly there are more experiences within the Forum to draw upon.

If everyone can keep posting updates and it will be interesting to see how many other roofs crack during the course of 2022. It would be nice to think there will be no more, but suspect this is unlikely.

Our cracked roof repair isn't covered under Warranty due to the age of the vehicle. Also, we have been told that there is no roof availability at present. I think we will just leave it for now and pick it up again next year when possibly there are more experiences within the Forum to draw upon.

If everyone can keep posting updates and it will be interesting to see how many other roofs crack during the course of 2022. It would be nice to think there will be no more, but suspect this is unlikely.

Hi all

My replacement roof arrived last week.

I am taking the MP to the dealer tomorrow.

I asked for the carbon plates to be fitted....unfortunately he told me he wasn't comfortable with fitting these plates on a new roof, as it would alter the warranty. He told me that the new roofs had been modified and reinforced to avoid futur cracks...He said the reference of the new roof is totally different than the original , and was pretty confident on that side...Not sure how to interpret that, but lets hope that the many many roof returns have encouraged Westfalia to modify them to avoid futur issues...

My replacement roof arrived last week.

I am taking the MP to the dealer tomorrow.

I asked for the carbon plates to be fitted....unfortunately he told me he wasn't comfortable with fitting these plates on a new roof, as it would alter the warranty. He told me that the new roofs had been modified and reinforced to avoid futur cracks...He said the reference of the new roof is totally different than the original , and was pretty confident on that side...Not sure how to interpret that, but lets hope that the many many roof returns have encouraged Westfalia to modify them to avoid futur issues...

Grand Tourismo

Top Poster

Good morning guys - I have updated the online questionnaire to include a section about roof cracking.

www.marcopoloownersclub.com

www.marcopoloownersclub.com

Please head over to the questionnaire and update your details or fill in if you can.

Please share this update on Fb and your other socials - strength in numbers and all that!

Can I suggest one of you nominate yourself to take a lead on this specific roof issue? Start to build a body of evidence which add's weight to your argument and then contact MBUK directly by mail.

One of the strong indicators of a batch issue rather than simple user error would be where the cracks are appearing and what form they take (crazing, vertical single runs, multiple cracks or whatever). Also understanding how old each roof is when the crack appears.

Build a database and try to ascertain from each user where, what and how large each crack is and formally submit this in support of your claim - you may get push back initially but as the evidence continues to build then you should get support from MBUK.

Anecdotally I had my roof replaced last week, the replacement roof was ordered in July and arrived late October (2021).

It was painted off-site, returned to the dealership and then fitted in around 4 days. All carried out by MB Northampton which did a perfect job.

I am not sure why just yet but it is definitely a quieter ride (completely quiet), no little squeaks or whatever.

Marco Polo and Horizon roof blistering questionnaire

Hi, If you are interested in helping out to document just how many MP and Horizon roofs have been affected by blistering please read on... Enclosed in this post is a link to an online questionnaire created in Google Forms, the idea is to create a permanent document for Marco Polo and Horizon...

Please head over to the questionnaire and update your details or fill in if you can.

Please share this update on Fb and your other socials - strength in numbers and all that!

Can I suggest one of you nominate yourself to take a lead on this specific roof issue? Start to build a body of evidence which add's weight to your argument and then contact MBUK directly by mail.

One of the strong indicators of a batch issue rather than simple user error would be where the cracks are appearing and what form they take (crazing, vertical single runs, multiple cracks or whatever). Also understanding how old each roof is when the crack appears.

Build a database and try to ascertain from each user where, what and how large each crack is and formally submit this in support of your claim - you may get push back initially but as the evidence continues to build then you should get support from MBUK.

Anecdotally I had my roof replaced last week, the replacement roof was ordered in July and arrived late October (2021).

It was painted off-site, returned to the dealership and then fitted in around 4 days. All carried out by MB Northampton which did a perfect job.

I am not sure why just yet but it is definitely a quieter ride (completely quiet), no little squeaks or whatever.

Sounds familiar….I have just found blisters on my 19 plate MP - another month and I would be outside the warranty. Some of the blisters are in straight lines and others are random.

I’m waiting to hear back from MB about replacing our second roof because it has developed the same blisters as the original.

Allistair Bell

New Member

Just Bought a 2018 MP and a crack has appeared on the day I drove it away. I have reported back to the Dealer and they have got in touch with Mercedes waiting to hear back.

An update to this post, we have a 2017 model thats just developed the dreaded cracked roof, spoke to my very helpfull MB parts department and he could find no mention of any carbon fibre reinforcing plates. Interestingly when checking his computator he told me 45 new roofs have been sold in the UK in the last 12 months, no current stock in UK. Westfalia must be making a killing here at £2200 + vat, really has put me off another MP in the future.

Anyone had a go at a repair? I think at £4000 + for a new one its got to be worth a go.

Anyone had a go at a repair? I think at £4000 + for a new one its got to be worth a go.

Hi Paul - be really helpful if you could outline what the repair involves,Update for posterity, cracked roof successfully repaired, if anyone picks this up in the future wanting to know how its done, let me know and i'll detail it.

Okey dokey here goes

So crack in the same spot as everyone elses, on the passenger side, sorry i didnt get any pics. All fibreglass supplys from East coast fibre glass supplies

1. To add insult to injury Mercedes lined the roof with a backed vinyl, this is a swine to get off and the worst part of the job, any new fibre glass will not adhere to this coating, it has to come off, i took about 400mm off, 250mm toward the front and 150mm toward the rear, figuring its the front that needs more support, go up to the top of the curve. I cut it straight down and across with a craft knife then managed to get the effected area off with a fairly sharp flat blade screwdriver, this will take a while. Be warned theres the shiny vinyl bit then a layer underneath, some came off in a one'er but a lot didnt. I used a 40 grit emery flapper wheel in a cordless drill for the final clean up, you have to get back to fibreglass for the epoxy to do its job.

2. You need a decent epoxy resin i used West systems 105 epoxy with the 205 hardener. 1kg was more than enough. Read the instructions then read again. Fibre glass matting was 300g chopped strand and then woven roving, cut these to size, get some epoxy into the crack then chock the roof front and back to close the crack, make sure its not going to move as its all going to be in situ for 48 hours

3. I thinkened the epoxy with colloidal silica (west systems) as you are working on a vertical surface so dont want the epoxy to run off, dont go mad it doesnt need to be to thick. Get a massive sheet of polythene on the side of the van and pop up roof fabric as once you get going its messy.

4. Using a resin brush, get a thick coat on the inside then your 1st layer has to be the chopped strand, apply more resin until wetted through, next layer is woven roving for additional strength, then repeat, i used 6 layers but 4 is probably enough, each layer has to be thorougherly wetted out, let it go off for maybe an hour then trim off all the excess glass cloth with a very sharp knife without disturbing the glass. I used one of the consolidation rollers when applying the matting to make sure everything is sat down nice.

5. Now resist the temptation to do anything else for at least 48 hours this is how long it takes to get to a load test strength. Do not touch a godam thing just let the van sit there to reflect on a) its poor behavior and b) to harden properly.

6. Key parts to this repair is the prep, you have to get all the vinyl crap off as the epoxy needs to be onto fibreglass, i cant stress this enough, use a mirror if you cant see properly. The bond between the roof and your first layer of glass will be the weakest link so it needs to be right. If you have never used fibreglass and resin before get some scrap plywood and have a go fibreglassing a 150mm square on it to get a feel for handling this stuff, watch some Youtube videos, wear latex gloves, read the instructions, dont be tempted to use the cheap Halfords glass kits, epoxy resin is the most expensive but also the strongest.

7. I cycled the roof up and down about 20 times (its the final locking part that puts the strain on it) i'm going to get a bit of use out of it in various conditions before i take it to my local body shop to fill and respray just the side, should be no more than £200, cost of resin and bits and bobs £100.

8. If you dont fancy this job i would suggest using someone who repairs boats rather than a body shop. They will have more experience with this type of repair. The body shop will do the final respray.

If anyone needs any further advise let me know

Paul

So crack in the same spot as everyone elses, on the passenger side, sorry i didnt get any pics. All fibreglass supplys from East coast fibre glass supplies

1. To add insult to injury Mercedes lined the roof with a backed vinyl, this is a swine to get off and the worst part of the job, any new fibre glass will not adhere to this coating, it has to come off, i took about 400mm off, 250mm toward the front and 150mm toward the rear, figuring its the front that needs more support, go up to the top of the curve. I cut it straight down and across with a craft knife then managed to get the effected area off with a fairly sharp flat blade screwdriver, this will take a while. Be warned theres the shiny vinyl bit then a layer underneath, some came off in a one'er but a lot didnt. I used a 40 grit emery flapper wheel in a cordless drill for the final clean up, you have to get back to fibreglass for the epoxy to do its job.

2. You need a decent epoxy resin i used West systems 105 epoxy with the 205 hardener. 1kg was more than enough. Read the instructions then read again. Fibre glass matting was 300g chopped strand and then woven roving, cut these to size, get some epoxy into the crack then chock the roof front and back to close the crack, make sure its not going to move as its all going to be in situ for 48 hours

3. I thinkened the epoxy with colloidal silica (west systems) as you are working on a vertical surface so dont want the epoxy to run off, dont go mad it doesnt need to be to thick. Get a massive sheet of polythene on the side of the van and pop up roof fabric as once you get going its messy.

4. Using a resin brush, get a thick coat on the inside then your 1st layer has to be the chopped strand, apply more resin until wetted through, next layer is woven roving for additional strength, then repeat, i used 6 layers but 4 is probably enough, each layer has to be thorougherly wetted out, let it go off for maybe an hour then trim off all the excess glass cloth with a very sharp knife without disturbing the glass. I used one of the consolidation rollers when applying the matting to make sure everything is sat down nice.

5. Now resist the temptation to do anything else for at least 48 hours this is how long it takes to get to a load test strength. Do not touch a godam thing just let the van sit there to reflect on a) its poor behavior and b) to harden properly.

6. Key parts to this repair is the prep, you have to get all the vinyl crap off as the epoxy needs to be onto fibreglass, i cant stress this enough, use a mirror if you cant see properly. The bond between the roof and your first layer of glass will be the weakest link so it needs to be right. If you have never used fibreglass and resin before get some scrap plywood and have a go fibreglassing a 150mm square on it to get a feel for handling this stuff, watch some Youtube videos, wear latex gloves, read the instructions, dont be tempted to use the cheap Halfords glass kits, epoxy resin is the most expensive but also the strongest.

7. I cycled the roof up and down about 20 times (its the final locking part that puts the strain on it) i'm going to get a bit of use out of it in various conditions before i take it to my local body shop to fill and respray just the side, should be no more than £200, cost of resin and bits and bobs £100.

8. If you dont fancy this job i would suggest using someone who repairs boats rather than a body shop. They will have more experience with this type of repair. The body shop will do the final respray.

If anyone needs any further advise let me know

Paul

ltoinel

New Member

The low cost solution I did in France ... But it works.

apollo-van.fr

apollo-van.fr

Toit du Van Marco Polo fissuré : Que faire ?

Fissure au toit de votre van Mercedes Marco Polo ? Découvrez les causes et solutions : renforcement en KEVLAR®/carbone, plaque d'acier ou barres en aluminium.